|

Client Profile

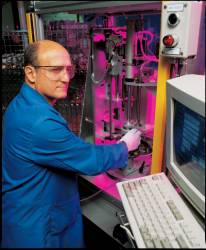

AUTECS (Automotive

Electronic Control Systems) is a joint venture operation between Unisia JEC (of Japan) and

The Robert Bosch Company (of Germany). The

company produces engine management components for the Automotive Original Equipment

manufacturers in the North American market.

The company resides in a eighty-one

thousand square foot facility located in Anderson, SC., and employs approximately three

hundred people, using state-of-the art high-volume equipment to assemble their products. Current product demand has the plant

running three shifts, six days a week. This medium-sized, growth-oriented company was

conceived in 1988 and shipped its first units in 1989.

AUTECS is QS9000 certified. They

intend to remain lean, competitive, and a technical leader, both on the shop floor and in

the office environment.

AUTECS

produces a variety of electronic Engine Control Unit and Transmission Control Unit as well

as a line of Air Flow sensing and control units for such demanding customers as Nissan,

Saturn, and Subaru-Isuzu.

In many cases, AUTECS is the sole supplier to the OEM. Therefore, on-time delivery and zero defect

quality is paramount.

Project Background

AUTECS

employed a nationally known Accounting/Consulting firm to perform a study and provide

recommendations on how they might achieve these goals.

The result of the study was a 46-page report of suggested improvements. A significant portion of those findings centered

on the fact that AUTECS had a very capable ERP

system (PRMS 8.4), but that the software was

under-utilized.

|

|

With these findings in mind, AUTECS began a search for an experienced PRMS consulting firm to help them better utilize

the software. After interviewing several

firms, AUTECS ultimately selected Systems Conversion Ltd., of Cartersville, Georgia.

This respected firm offered them the

most experienced consulting personnel, the largest breadth of technical resources, and a

superior project-implementation methodology.

Project Planning

Project

Planning began with a formal Needs Survey of AUTECS

by consultants from Systems Conversion Ltd. SCL found that:

·

AUTECS was utilizing about

20-25% of the capability of the system.

· A number of

“home-grown” processes had been developed in place of system processes.

· The cause of the

under-utilization and circumventing processes was a lack of knowledge and understanding

about PRMS.

|